If you are interested in a Raspberry Pi-based Pool Automation System, please share your thoughts here.

We will try to draw conclusions about the best set of specifications, and hope to bring it to life soon.

In short, please help us define the board level inputs, outputs and communication interfaces required to automate your pool.

Hi Guys,

As per your email, I know something about pools (my dad used to sell and install them, and was an electrician and plumber to boot).

I am an electrical engineer, that dabbles in home automation and digital control systems. My comments are as follows.

This might be a great idea, but you might want to target a slightly wider audience/customer base. Pools have a lot of similarities (but simpler), than aquariums!

There are a LOT more aquariums out there than pools, but the combination is a large market. Yes there are aquarium controllers out there already, but they are mostly closed, proprietary non expandable /non-customizable. You might kill two birds with one stone if you take this into your design considerations,

Some features of both pool and aquarium controllers:

monitoring:

Temperature monitoring (pools can use multiple temps if they have a solar heater loop.... If temp in loop is greater than temp in pool, turn on loop pump..etc

loop inlet/loop outlet/main temp/ outdoor (air) temp

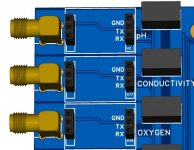

PH monitoring (should be able to use off the shelf scientific / industrial pH sensors - calibration etc.

ORP monitoring

Sunlight? monitoring ( for day /night determination)

REAL TIME CLOCK

Control:

circulating pumps (2 at least?) main pump aux pump, solar loops?

heater on/off (timer, or setpoints (from temperature monitor, or logic driven)

pH doser control (can be dosing pump? or just relay to control) dosing motor (generally a peristaltic pump)

ORP control ( relay output, generally for OZONE generator).

Lighting control (pools - underwater lights, outdoor lights etc)

lighting controls /(aquarium: LED/HID, etc) timer based, generally 2 -3 outlets for staging (separate timers for moonlight.daylight etc. BONUS - dimming of LED lights for ramp up ramp down.

Aquarium only:

FEEDER output: feeder timer set for 1,2,3,4 times per day. Relay output. Logic also turns of certain circulation pumps.

Filter (sump) pump control (logic, and timer).

4x Circulation pumps (timer on/off, cyclical, logic triggers)

Protein skimmer pump control (relay on off, timer, logic driven)

Logic circuitry.

Simple logic for on off

Alarm conditions (overtemp, pH out of range, ORP out of range, no circulation

Display/notifications (from software)

Email, SMS, local display, phone app?

WiFi enabled? WiFi reprogrammable (OTA)

Hope this helps getting your creative juices flowing.

Best will be open design, expandable, customizable.

Let me know what you think...!